We offer a true end-to-end Full-Service Manufacturing solution, designed to take your product from concept to completion—all under one roof. Our process begins with technical consultation and design optimization, where our dedicated technologists ensure your product is production-ready. We provide rapid prototyping, efficient material sourcing, and fully managed supplier coordination to streamline your supply chain.

PIT Group Services

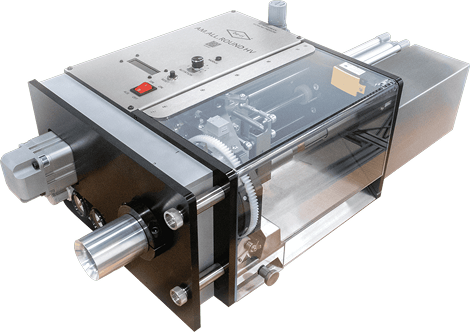

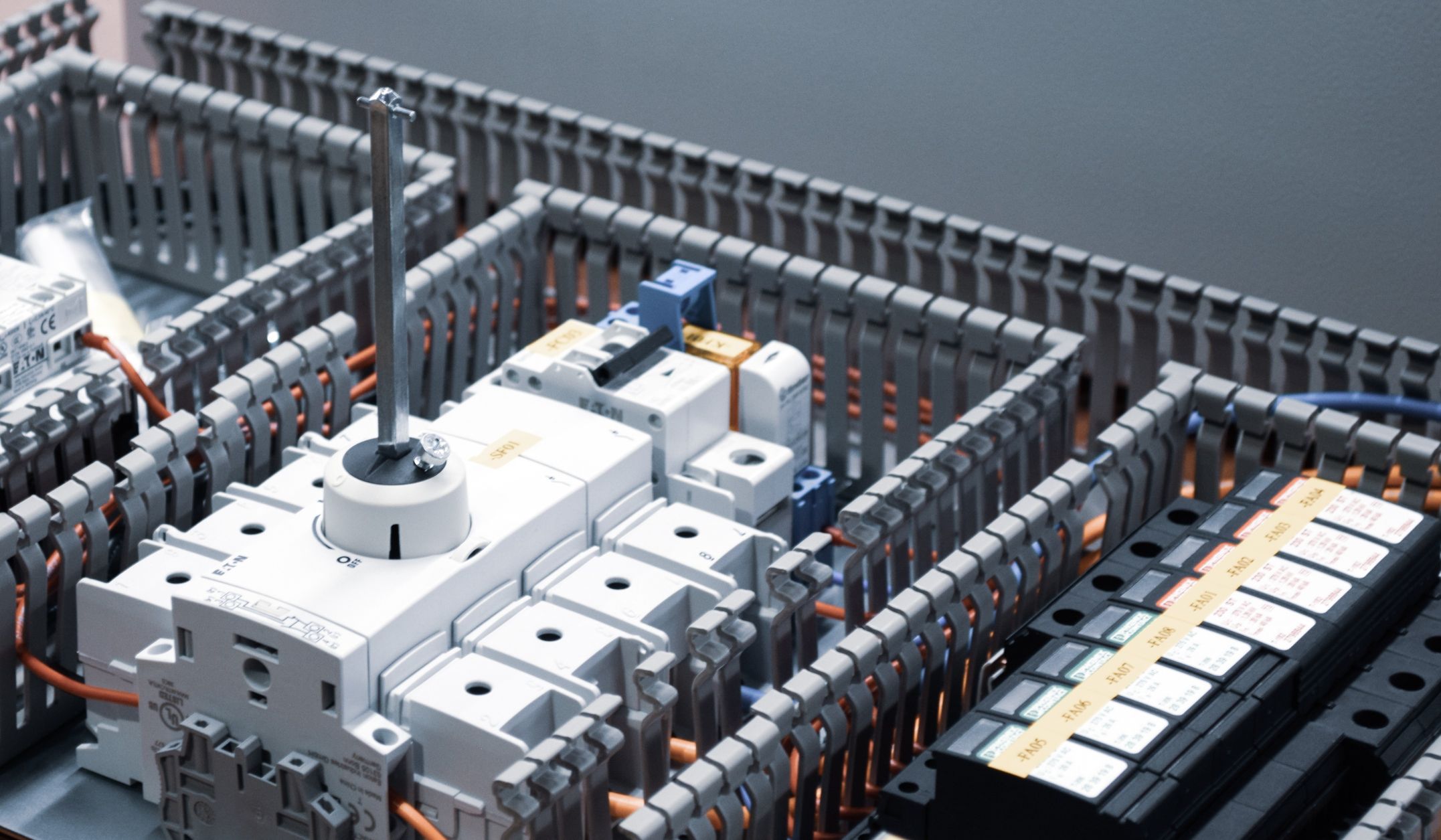

Full-service manufacturing, cable assemblies, control cabinets, metal plate processing and electronics manufacturing.

Our Metal Plate Processing service offers a complete range of solutions for precision metal fabrication, including laser cutting, shearing, bending, rolling, and surface finishing.

Using advanced equipment and techniques, we ensure high-quality results with accuracy, consistency, and durability for every project.

Sectors We Work With

PIT Group works with various industries, offering specialized solutions designed to meet the unique needs of each field. We provide high-precision assemblies, custom manufacturing, and advanced soldering services, ensuring the highest standards of quality, reliability, and performance. Our expertise supports critical systems, enhancing efficiency and safety across a wide range of applications.

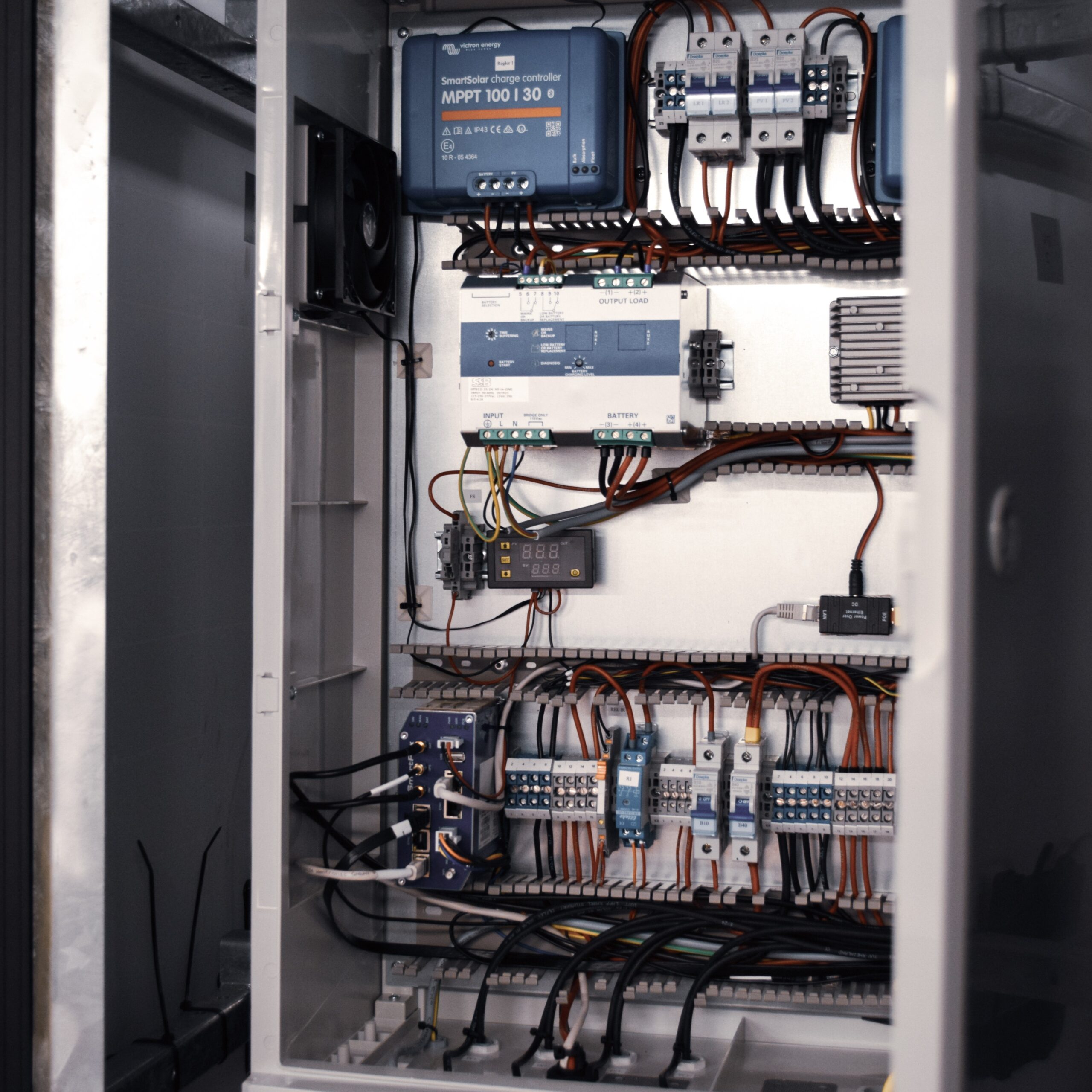

Control cabinets and systems that support the operation of renewable energy installations.

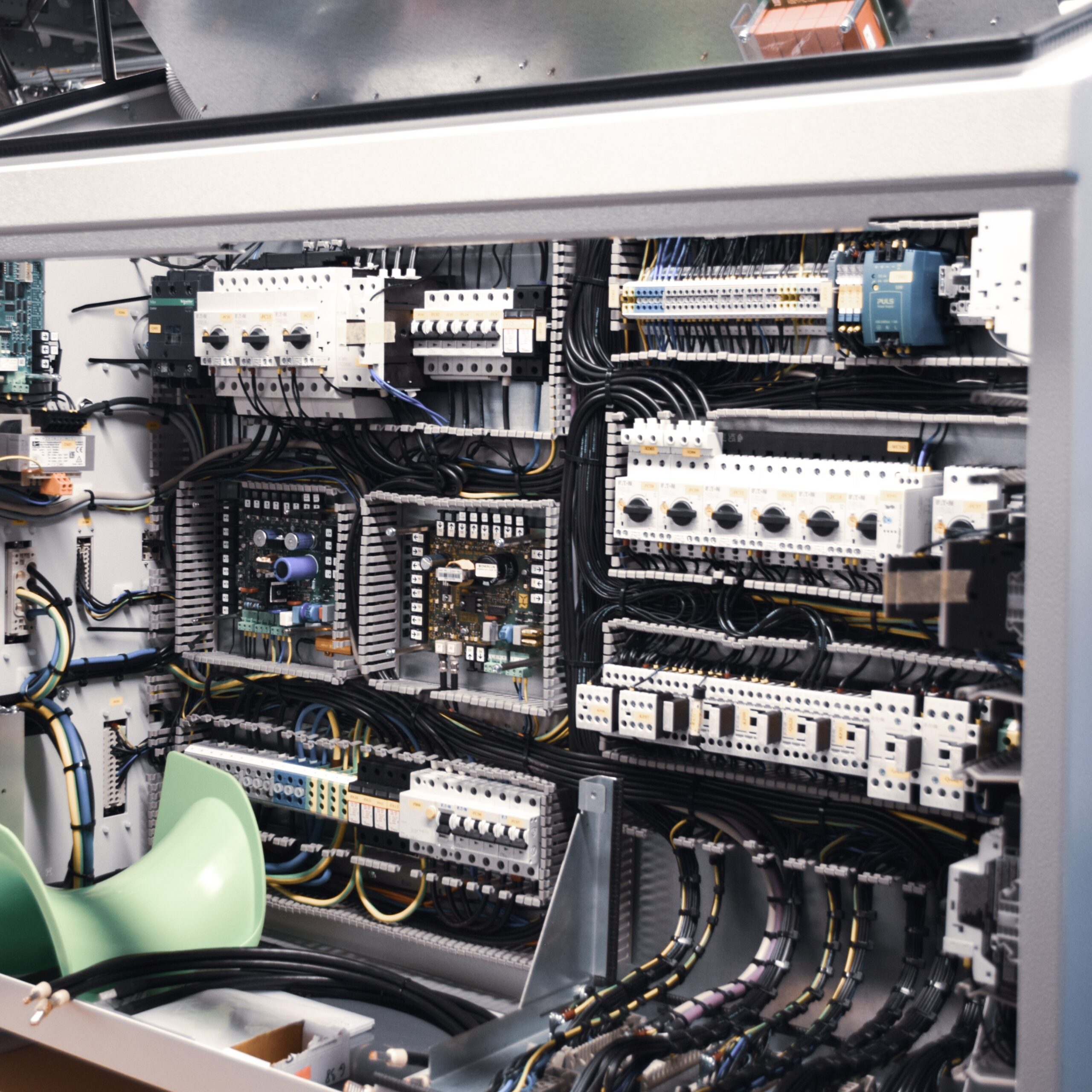

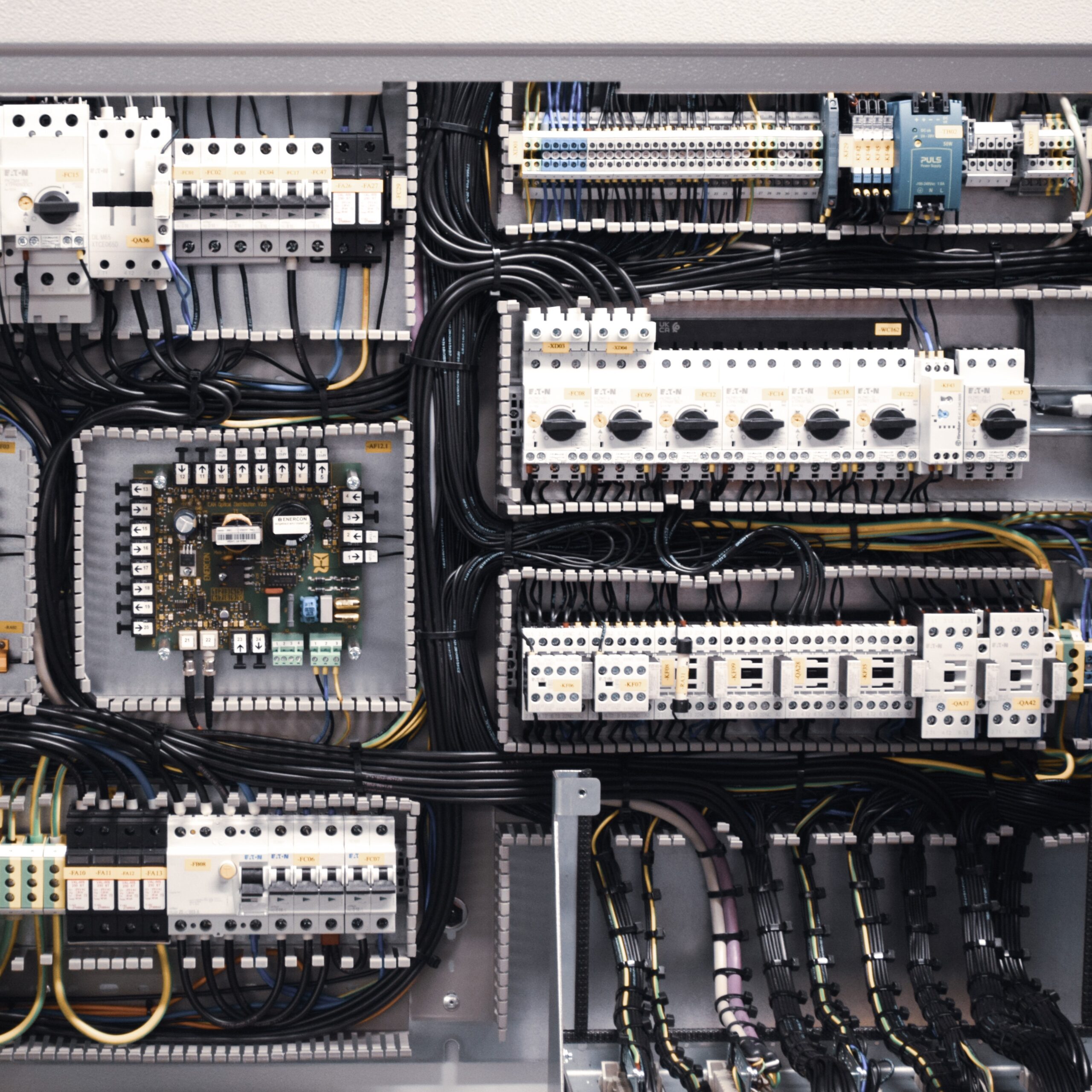

Components and systems that support the control and operation of automated systems.

Components used in machinery to enable rotational movement and support operational functionality.

Systems that transport medical samples and other items within healthcare facilities, supporting efficient internal logistics.

Components that are used in various vehicle systems, supporting their assembly and operation.

Portable surveillance systems to support monitoring and safety in temporary or changing environments.

Process

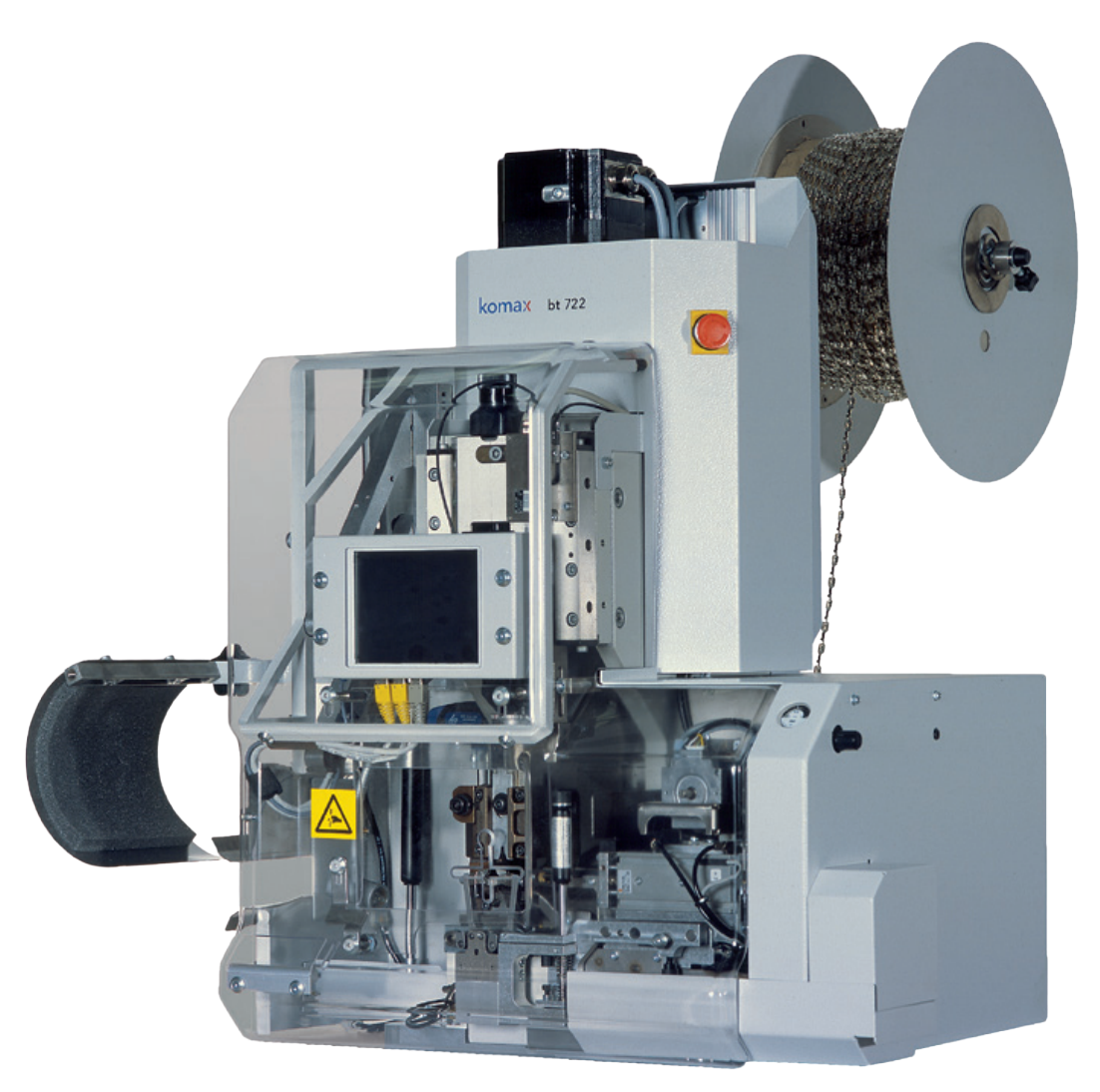

Equipment We Trust

Contact

info@pit-deutschland.eu

+49 4435 973 6403